Whether it’s jewelry, electronics, or cosmetics, every product packed in a rigid box is considered luxurious and high-end. Even if you’re just starting a new business, these boxes can easily set your brand apart by delivering a perfect first impression and a memorable unboxing experience. So, how are rigid boxes made? And what products are best to display in these boxes? Let’s dive in.

Step-by-Step Guide to Making Rigid Boxes

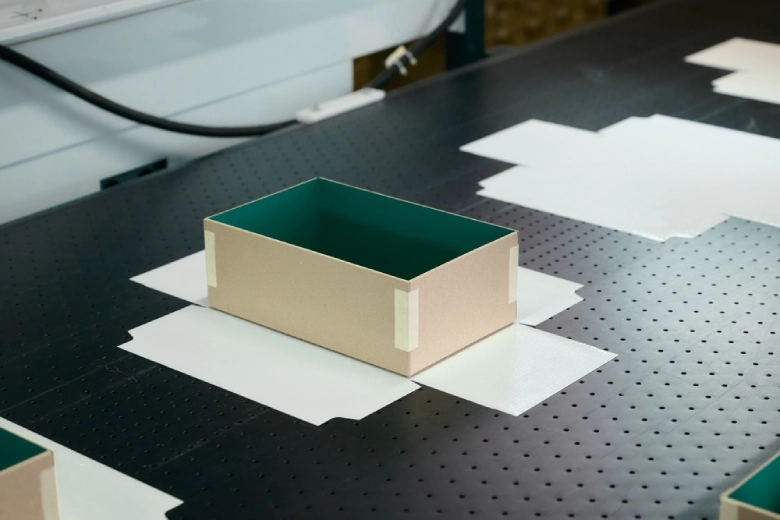

Considering their sturdiness and smooth texture, we must say that the process of making custom rigid boxes takes time and attention to detail. Let’s break down the steps behind the manufacturing of these innovative boxes!

Choosing the Best Material

Rigid boxes, also known as setup boxes, are made from a combination of various materials.

- Core materials: Chipboard (also known as greyboard), cardboard, and kraft

- Covering materials: Textured, patterned, or coated papers

The thickness of rigid stock ranges from 2 to 3mm (36pt to 48pt), depending on the level of protection your product requires. Thicker boxes are suitable for heavier or more delicate items, while thinner boxes might be sufficient for lighter products.

Box Sizing

Once you have decided on the material to use in producing a rigid box, the next step is to determine the precise dimensions of the box, ensuring it fits your product perfectly and meets its functional requirements. Moreover, you should also consider adding custom inserts or padding when measuring the box.

Folding

Customized rigid boxes are generally not designed to be folded flat for storage or shipping. The folding process here involves scoring, folding, and securing the chipboard to form the base and sides.

Thanks to the advanced die-cutting technique, you can now get personalized rigid boxes in unique shapes, forms, and styles, including drawer boxes, two-piece boxes, shoulder neck boxes, and more.

Printing

The printing step in rigid box production revolves around printing your artwork, graphics, business logo, and other branding elements onto a substrate (such as wrapping paper), which is then wrapped around the rigid board. The two printing techniques that work well here are digital and offset.

To make your business look more professional, consider using an embossing or debossing technique to make your business logo stand out on the box. Ultimately, there are excellent finishes, such as matte, gloss, or spot UV coating, that will elevate your product display through rigid boxes with logo.

Wrapping

The wrapping step involves applying a printed and potentially laminated sheet of paper, fabric, or other material (the “wrap”) to the pre-formed chipboard base of the box. Then, this wrap will be carefully glued to the chipboard, ensuring a smooth, tight fit for the interior of the box. Furthermore, the wrap essentially serves as the outer surface of the box, showcasing your design and branding elements.

From choosing the material, sizing, folding, to printing and wrapping, the entire rigid box production is surely time-consuming. Thus, it’s no wonder that these boxes might be, somehow, a bit costly, but they are surely worth the investment.

Why Is the Rigid Box Manufacturing Process Difficult?

Manufacturing rigid boxes is a complex process due to several key factors that set them apart from standard packaging.

Below are the factors that make rigid box manufacturing difficult.

- Multi-step assembly: Unlike simple folding cartons, rigid box manufacturing involves multiple precise steps, including cutting thick chipboard, scoring it for sharp folds, and wrapping it with decorative outer paper.

- The quality standards: Rigid boxes are designed for premium products, so the quality standards are very high. Hence,no minor defect can be tolerated.

- Skilled labor: Even with modern automation, skilled manual labor is still required for precise assembly and quality checks.

Despite the complex process of rigid box manufacturing, luxury brands still prefer the boxes to pack and present their high-end products.

What Products Are Best to Display in Rigid Boxes?

Premium rigid boxes have the power to elevate the perceived value of any products you wish to display.

Here are various products that are best displayed in these boxes:

- Jewelry

- Electronics

- Cosmetics

- Watches

- Perfumes

- Gift sets

- Apparel

- Cigars

- Other high-end products

Overall, custom rigid boxes are ideal for various products where presentation and protection are top priorities. Most importantly, the durable construction of the boxes ensures your products remain safe and sound, even in a harsh shipping journey.

In Summary

Undoubtedly, considering their sturdiness and smooth texture, it is clear that the process of making custom rigid boxes requires time and attention to detail. However, whether it’s jewelry, electronics, or cosmetics, every product packed in these boxes is considered luxurious and high-end. Now that you understand their complex manufacturing process, you can appreciate that rigid boxes are a worthwhile investment.

FAQs

What are the core materials in rigid box production?

The core materials in rigid box production include chipboard (also known as greyboard), cardboard, and kraft.

What is the best thickness of a rigid box?

The material thickness of a rigid box ranges from 2 to 3mm (36pt to 48pt), depending on the level of protection your product requires.

What is involved in the folding step of rigid box production?

Customized rigid boxes are generally not designed to be folded flat for storage or shipping. Thus, the folding process here involves scoring, folding, and securing the chipboard to form the base and sides.

What products are best to display in custom rigid boxes?

From jewelry, electronics, cosmetics, and premium gift sets, rigid boxes have the power to elevate the perceived value of any products you wish to display.