Safely ship, store, and present your products with custom mailer boxes designed for durability, branding, and customer experience. Whether you run an e-commerce store, a subscription service, or a retail brand, our mailer boxes provide reliable protection while creating a memorable unboxing experience.

At Custom Rigid Boxes, we manufacture premium custom mailer boxes that combine strength, visual appeal, and full customization. From shipping lightweight products to delivering luxury items, our mailer packaging solutions are built to perform.

Our custom mailer boxes are produced using high-strength cardboard, kraft, and chipboard materials that ensure your products remain protected during transit. These boxes resist bending, crushing, and moisture, making them suitable for both short-distance and long-distance shipping.

Each mailer box is carefully engineered to maintain its structure while delivering a clean, professional presentation.

We offer fully customized sizes and box styles so your products fit perfectly without unnecessary movement. Snug-fit mailer boxes help reduce damage and shipping costs.

Optional closure features include:

These features improve security while enhancing the unboxing experience.

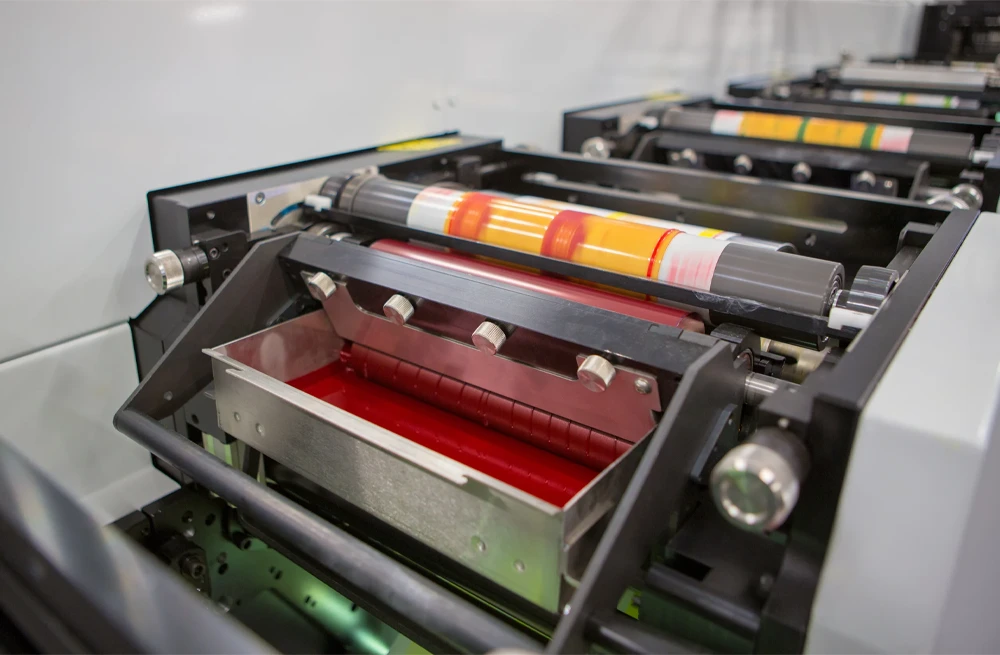

Stand out from competitors with custom printed mailer boxes that reflect your brand identity. Using advanced digital and offset printing, we deliver sharp graphics, consistent colors, and professional results.

Printing options include:

Our design experts are available to assist you at no extra cost.

Enhance the visual appeal of your packaging with premium finishes that elevate brand perception:

For a refined brand touch, emboss or deboss your logo directly onto the box surface.

Our mailer boxes are widely used for:

Their durability and customization make them suitable across multiple industries.

High-quality packaging does not have to be expensive. We offer custom mailer boxes at wholesale prices, allowing you to scale without exceeding your budget.

Order exactly what you need, when you need it.

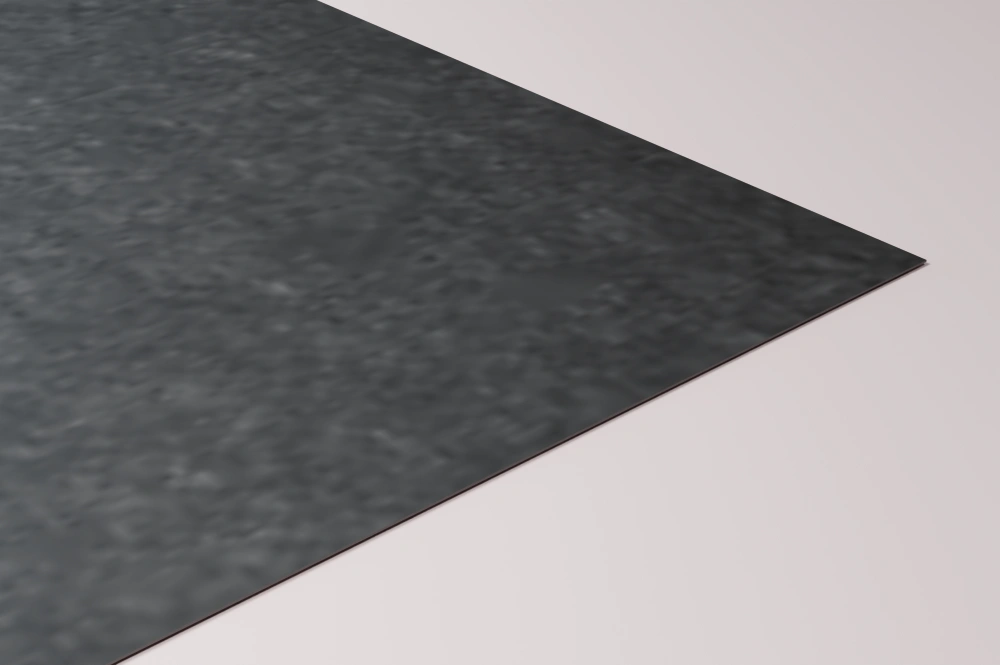

Dense grey board produced from recycled paper pulp and widely used as the structural core of rigid boxes. It offers excellent rigidity, high load-bearing strength, and long-term shape stability, making it ideal for premium, luxury, and heavy-duty packaging applications.

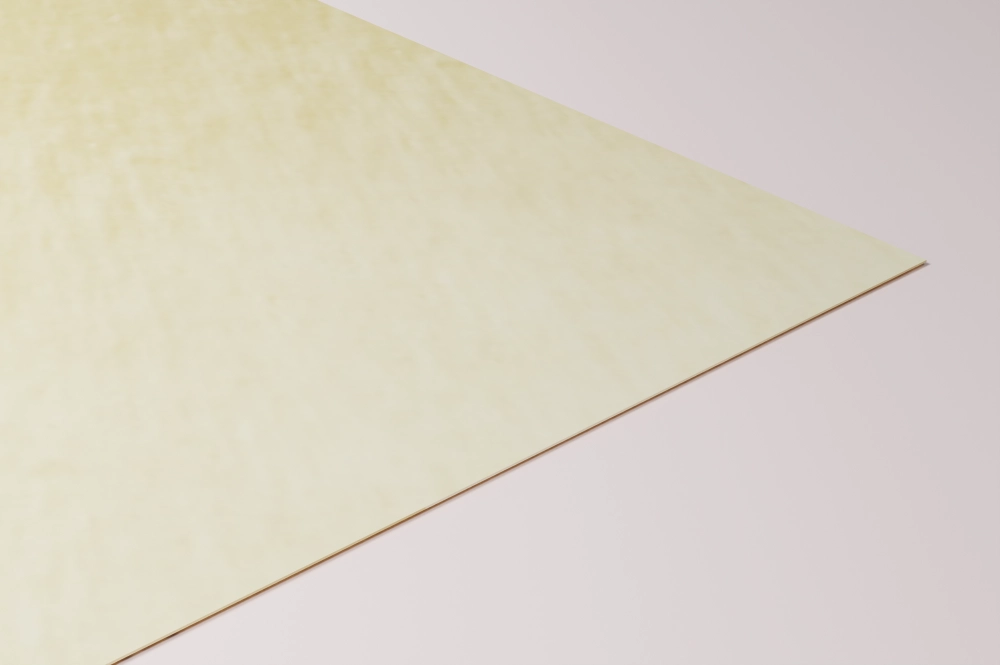

Layered chipboard constructed with a smooth coated front surface and a strong uncoated reverse side. This material provides a balanced combination of print quality and structural support, commonly used for rigid box bases, lids, and reinforced panels.

Thick, dense chipboard layered and compressed for strength, available between 36pt-120pt, providing superior protection and a high-end feel for unforgettable unboxing experiences.

High-quality printing method using CMYK or Pantone color systems. Delivers precise color accuracy, sharp details, and consistent output, making it ideal for large production runs.

Plate-free printing directly from digital files. Best suited for short runs, quick turnaround, and design variations without compromising print clarity.

Uses flexible printing plates to transfer ink efficiently. Often applied in packaging components where speed and consistency are essential.

High-speed printing process using engraved cylinders. Known for detailed imagery and uniform color reproduction in large-volume production.

Ink is pressed through a mesh screen to produce bold, vibrant, and textured designs, commonly used for specialty graphics and accent printing.

Water-based coating that protects printed surfaces and dries quickly, allowing safe handling and stacking.

Ultraviolet-cured coating that hardens instantly to provide resistance against scratches and scuffs.

Selective UV application used to highlight logos, patterns, or text by creating contrast and shine.

Liquid coating applied to enhance surface smoothness and improve print durability.

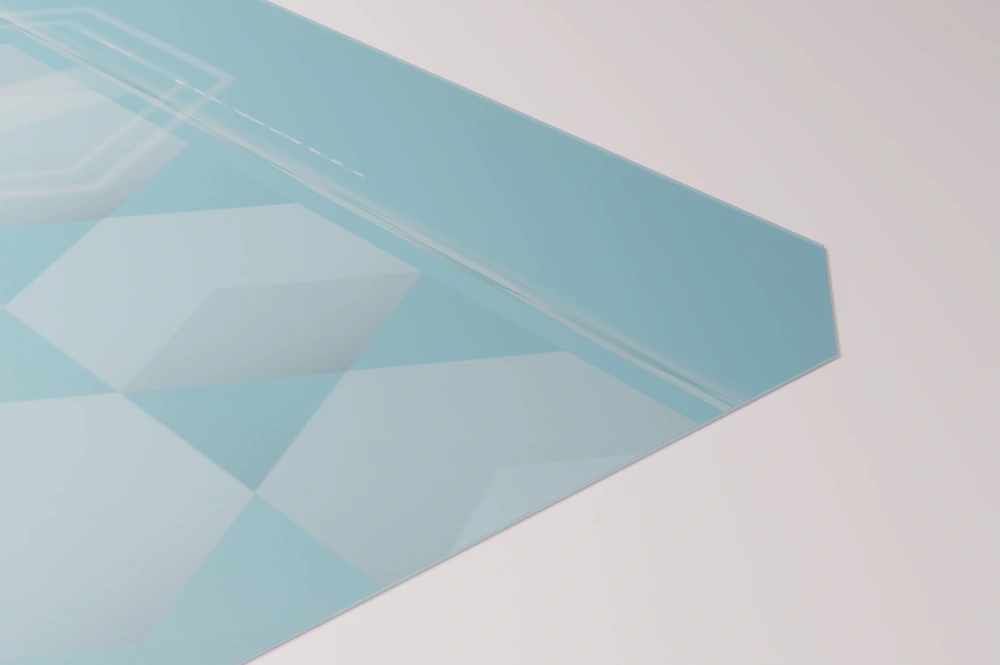

Protective plastic film that reinforces printed surfaces and increases resistance to moisture and wear.

Special lamination that delivers a smooth, velvety feel, enhancing the perception of luxury and tactile experience.

Scratch-resistant lamination designed to maintain surface clarity during frequent handling.

Application of metallic foils such as gold, silver, rose gold, or custom shades to create reflective design elements.

Processes that raise or recess designs into the surface, adding depth and tactile engagement.

Special finishing methods that introduce patterned or grain-like effects to printed surfaces.

UV coating applied in elevated patterns to produce a three-dimensional, tactile effect.

Foil treatment with rainbow-like reflective properties that creates dynamic visual movement.

Advanced technique combining embossing or debossing with foil stamping for enhanced dimensional impact.

Precision-cut openings with PET, PVC, or plastic-free options that allow product visibility while preserving protection.

Carrying features available in rope, ribbon, or die-cut integrated styles for improved portability.

Built-in locking systems designed to limit easy access and improve product safety.

Embedded magnets that secure lids with a firm and repeatable closing action.

Decorative and functional ribbons used to simplify opening drawer-style rigid boxes.

EVA Foam: Ethylene-vinyl acetate (EVA) foam, known for high density, excellent cushioning.

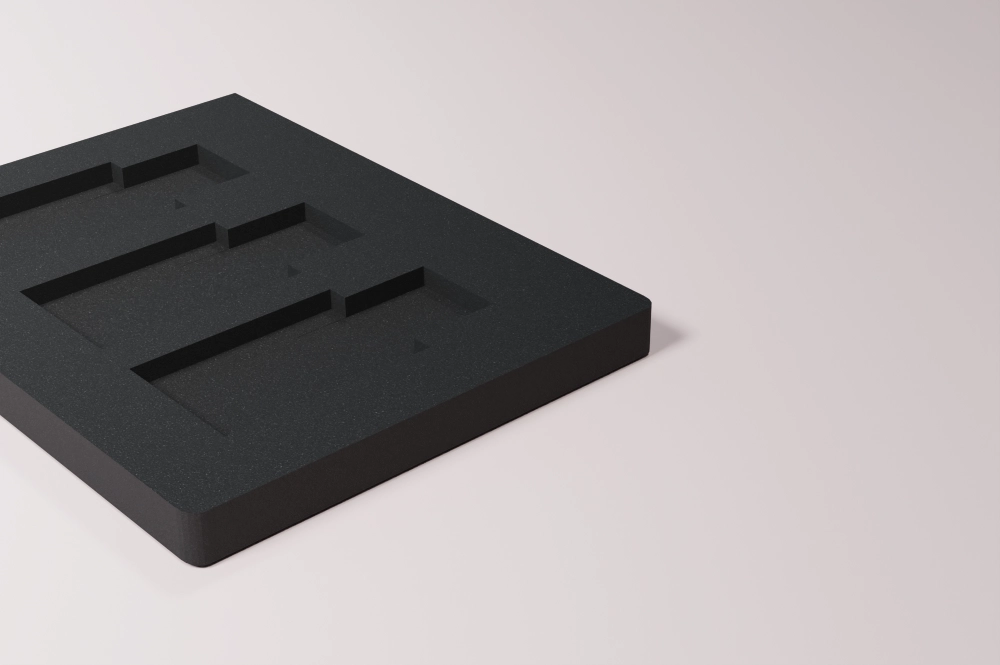

Cardboard Inserts: Sturdy corrugated cardboard (with wavy lines) or paperboard.

Interior packaging inserts, made from paperboard or corrugated cardboard, that create separate compartments to organize, protect, and present multiple items within a single luxury rigid box.

Box Type | Luxury, Durable, and Premium Rigid Packaging |

Material Options | Greyboard (1.5mm – 3mm) wrapped with Art Paper, Kraft Paper, or Specialty Paper |

Printing Techniques | CMYK, PMS, Offset, Digital, UV Printing |

Finishing Options | Matte / Gloss Lamination, Soft-Touch, Spot UV, Foil Stamping (Gold/Silver/Rose Gold), Embossing, Debossing |

Customization | Fully Custom Size, Shape, and Design |

Add-ons | Ribbon Handles, Magnetic Closures, EVA Foam Inserts, Velvet Inserts, Transparent Windows |

MOQ | No Minimum Order Quantity (Low MOQ Available) |

Dimensions | Customizable to Any Required Size |

Production Time | 10–12 Business Days (Rush Orders Available) |

Shipping Options | Worldwide Delivery via Air or Sea (DDP Available) |

Sustainability | Recyclable, Eco-Friendly, and FSC-Certified Materials |

Use Cases | Luxury Product Packaging, Gift Boxes, Jewelry Boxes, Cosmetic Boxes, Candle Boxes, Apparel Packaging |

| Prototyping | Sample & 3D Mockup Available on Request |

| Quality Assurance | 100% Quality Checked Before Dispatch |

Ordered hinged lid boxes for my cosmetic products from the company and loving the layout they design. The boxes met my expectations for secure, elegant presentation I needed for sensitive cosmetics. Plus, I got a great discount, too. Highly recommended!