Have you ever held a shiny-looking rigid box or a smooth business card and wondered how it got that sleek finish? Well, you’re likely touching a layer of aqueous coating. This finishing technique is popular in product packaging, publishing, and marketing materials. But what exactly is aqueous coating, and why is it so widely used? Let’s explore this modern finishing technique further!

What Is Aqueous (AQ) Coating?

Aqueous (AQ) coating is a water-based finish applied to printed materials to protect the surface and enhance its appearance. It’s typically used right after the ink is printed and before the sheets are dried. The result? A thin, transparent layer that adds shine, reduces smudges, and improves durability.

As the name suggests, aqueous coating in printing is made with water and natural polymers, making it recyclable and safer for the environment.

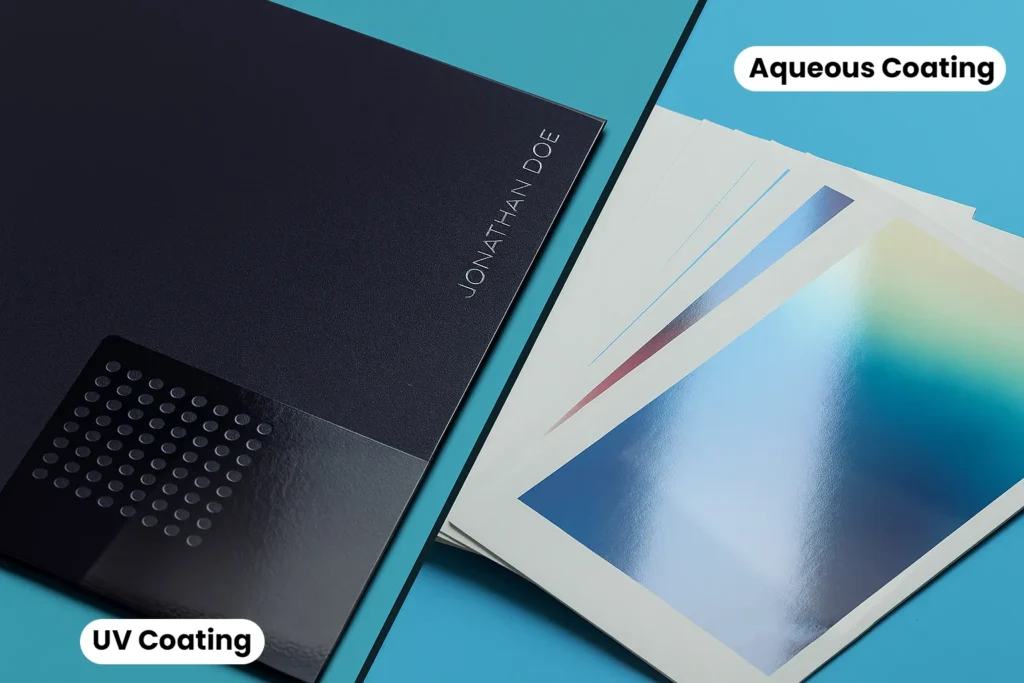

What Is the Difference Between Aqueous Coating and UV Coating?

Both aqueous coating and UV coating are protective finishes applied to print materials, such as brochures, flyers, postcards, business cards, and custom packaging.

However, although both coatings are used to enhance the durability and appearance of printed pieces, there are several key differences between the two.

Below are the key features that differentiate the two finishes.

| Feature | Aqueous Coating | UV Coating |

| Formulation | Water and water-soluble polymers | Chemical-based and made entirely of polymer resin |

| Curing Process | Fast dried | Fast dried |

| Appearance | It can only be applied as a flood coat, not as a spot coat | It can be applied as a flood coat over an entire sheet, or as a spot coat to selected areas |

| Durability | It offers good resistance against fingerprints, rubs, and scuffs | It provides better resistance against scratches and abrasions |

| Flexibility | Highly flexible—the preferred choice for printed pieces that will need to be folded. | A harder coating, it is not as flexible as an Aqueous coating |

| Cost | Economical | Slightly expensive |

Types of Aqueous Coating

There are several types of aqueous coatings, each offering a unique look and feel. It all depends on your business needs. Perhaps you’re questioning: “What is aqueous coating on business cards?” Or maybe you’re wondering which one

- Glossy aqueous coating: Adds a shiny, reflective finish. Ideal for brochures, catalogs, and promotional flyers.

- Matte aqueous coating: Offers a smooth, non-glossy finish. Perfect for elegant designs, such as invitations or rigid boxes for luxury products.

- Satin aqueous coating: A balance between gloss and matte. Great for professional documents and presentations.

- Soft-touch aqueous coating: Feels velvety to the touch. Often used for jewelry boxes and business cards.

Each type enhances the visual appeal while protecting the printed surface from fingerprints, scratches, and fading.

The Process of Aqueous Coating

Now that you understand different types of AQ coating, how does the process of this finishing start and is completed?

Here’s how aqueous coating is applied.

- Printing: The design is printed using offset or digital printing methods.

- Coating Application: A thin layer of aqueous coating is applied using rollers or spray systems.

- Drying: The coated sheets pass through a heated air system to dry quickly.

- Finishing: Once dried, the sheets are trimmed, folded, or bound as needed.

Overall, this seamless process ensures that the coating bonds well with the ink and paper, resulting in a polished and protected final product.

Ultimately, this finish is carefully applied to ensure no wrinkles or curls during the process. After the coating is applied, the sheet passes through a heated air system for quick drying.

Is Aqueous Coating Food Safe?

Yes, aqueous coating is generally considered food-safe when used on indirect food packaging. Since it’s water-based and free from harmful solvents, this technique is often used on items like cereal boxes, snack packaging, and beverage labels.

However, for direct food contact (like wrappers touching food), you will need specialized coatings approved by food safety authorities.

Is Aqueous Coating Waterproof?

Yes, aqueous coating is water-resistant—but it’s not fully waterproof. This method can handle light moisture, such as humidity or a few drops of water, without smearing or damage. Yet, it might not be suitable for materials exposed to heavy water or outdoor conditions.

For waterproof needs, UV coating or lamination may be better options. Yet, aqueous coating offers decent protection for everyday use and indoor environments.

What Is the Most Suitable Aqueous Coating Paper?

Mostly, suitable papers for aqueous coating are those with a glossy, matte, or silk finish, as their smooth surfaces ensure consistent and high-quality results. While you can opt for uncoated or recycled papers, they require more caution due to their variable absorption, which can lead to an inconsistent finish.

The Benefits of Aqueous Coating

Many business owners across different industries prefer aqueous coating, and for some valid reasons.

This excellent finish offers several benefits that no business should overlook.

- Eco-Friendly: Water-based and recyclable, making it a sustainable choice.

- Cost-Effective: Less expensive than UV or lamination finishes.

- Fast Drying: Speeds up production time and reduces smudging.

- Enhanced Appearance: Adds visual appeal with gloss, matte, or satin effects.

- Durability: Protects against fingerprints, scratches, and fading.

- Safe for Product Packaging: Suitable for indirect food contact and consumer goods.

Ultimately, all those benefits make aqueous coating a go-to solution for high-quality, responsible printing.

Final Thoughts

Aqueous coating is a finishing technique popular in product packaging, publishing, and marketing materials. It’s a water-based finish applied to printed materials to protect the surface and enhance its appearance.

There are several types of aqueous coatings, each offering a unique look and feel. It all depends on your business needs. Whatever type you choose, its seamless process ensures that the coating bonds well with the ink and paper, resulting in a polished and protected final product.

This excellent finish offers several benefits that no business should overlook, including being eco-friendly, cost-effective, fast-drying, enhancing appearance, durable, and safe for product packaging.

So, if you’re thinking of applying aqueous coating and making your custom boxes look sleek and classier, you can work with the packaging experts at Custom Rigid Boxes!

FAQs

What is aqueous (AQ) coating?

Aqueous (AQ) coating is a water-based finish applied to printed materials to protect the surface and enhance its appearance.

What are the types of aqueous coating?

There are several types of aqueous coatings, including glossy, matte, satin, and Soft-touch aqueous coatings.

Is aqueous coating food safe?

Yes, aqueous coating is generally considered food-safe when used on indirect food packaging. Since it’s water-based and free from harmful solvents, this technique is often used on items like cereal boxes, snack packaging, and beverage labels.

What are the benefits of applying an aqueous coating?

This excellent finish offers several benefits that no business should overlook, including being eco-friendly, cost-effective, fast-drying, enhancing appearance, durable, and safe for product packaging.